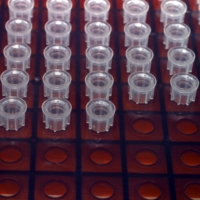

The application used to operate the transfer machine is an integral part of the customer’s manufacturing, quality control, and inventory tracking process. A pallet of several small parts is presented to the machine. The machine reads each part’s serial number using the vision camera. The pallet is sent to a quality inspection station and the inspection results are returned to the application, which logs each serial number and result to database. The machine transfers parts that pass inspection to a separate pallet for further downstream processing. Finally, each part’s serial number is re-verified prior to shipment.