The client came to DMC with a request to enhance the reliability of their machine controls. Their original automation platform was not well-known and was running on a PC as opposed to a PLC. If the computer crashed, it would stop production. At a facility that processes close to 1000 cuts an hour, 5-10 minutes spent rebooting a system could result if substantial losses in output. DMC converted the machine to a Siemens S7-1500T PLC with S120 Servo Drives while maintaining all the original system functionality. This not only allowed for improved reliability but also guaranteed global technical support with Siemens integrators located worldwide. These features aided our client in selling to their end customers and speed up future commissioning.

In addition to enhanced reliability, DMC built a flexible code base with parameters that can be adjusted directly from the HMI. This meant that the machine could be easily modified to create custom-tailored solutions for each factory installation.

Within a year of commissioning the first machine, DMC has now built 5 additional machines that are deployed around the world. With ongoing requests coming from the end clients, DMC’s flexible code is quickly modified to meet customer’s requests. One example of this is when DMC was able to install an entire machine in one day. This short deadline was able to be met due to the benefit of consistently using one platform throughout the machine.

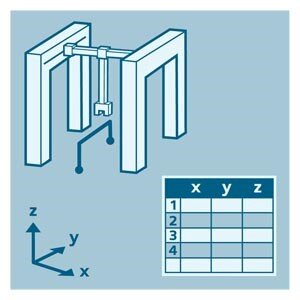

In the meat industry, precision while cutting is a high priority. When a few inches in the wrong place could result in wasting an expensive cut of meat, DMC needed to be able to increase accuracy. By integrating the Kinematic Technology Object into the client’s machine, future users can make more complicated cuts with increased accuracy.

Learn more about DMC’s work in the food and beverage industry and our Siemens expertise. Contact us for any project inquiries.